Industries

Regal Research acts as the manufacturing arm for many leading technology-based OEM’s across multiple industries. Our comprehensive in-house capabilities include precision sheet metal fabrication, CNC machining, automated and manual weld, plating, finishing & painting, electromechanical assembly, complete product manufacturing, functional testing, custom packaging, and warehousing. We want to be your turnkey manufacturing solution from concept to full rate production.

- Medical & Mobility

- Semiconductor

- Industrial

- Infrastructure

- Aerospace & Defense

- Communications

- Data Centers

Medical & Mobility

Regal Research builds such items as medical diagnostic equipment, surgical shelving, medical kiosks, and mobility carts for several leading OEMs. Our in-house turnkey manufacturing services include product engineering support, sheet metal forming, precision machining, welding, plating, painting, hardware insertion, unit wiring, electromechanical assembly, product testing, custom packaging, and warehousing.

From custom enclosures and cabinets to complex medical stands, the routine production of a stable product line allows us to suggest quality improvements and cost savings that benefit our customers. This value-added service is a tangible benefit of Regal’s vast experience, tremendous in-house manufacturing capabilities, and skilled workforce.

- Medical Equipment Enclosures

- Surgical Shelving and Drawers

- Mobility Carts (Manual and Electric)

- Telemedicine Kiosks

- Bacterial Detection Equipment

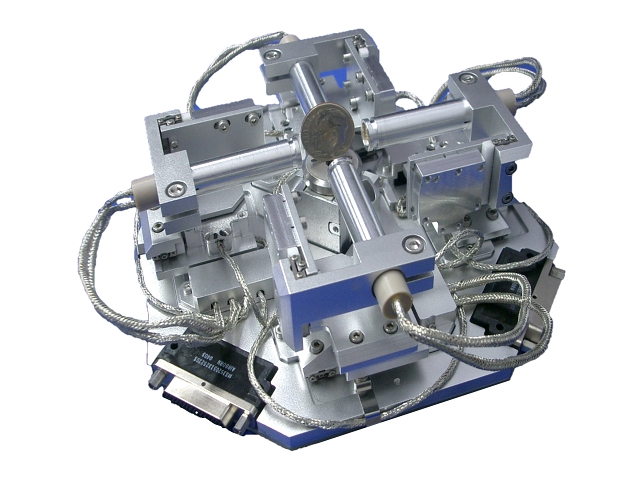

Semiconductor

The recent explosion in new technologies such as artificial Intelligence (AI), next generation cellular communications, and advanced medical diagnostics equipment is driving a tremendous demand for semiconductor electronics and the wafter fabrication equipment that produces them. For over two decades, Regal Research has been a key provider of precision machined parts and assemblies for some of the world’s leading OEMs in the field of semiconductor wafer fabrication and test equipment.

- Precision Weldments

- Equipment Panels and Doors

- Carriers and Carts

- Brackets and Holders

- Sheet Metal and Machined Components

- Custom Electromechanical Sub-Assemblies

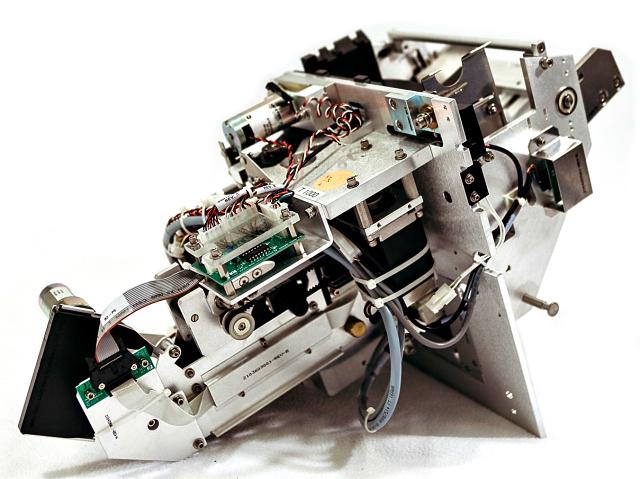

Industrial

For more than 40 years, Regal Research has built products for a number of large OEMs supplying products and equipment to the Industrial automation market. Complex electromechanical assemblies such as automated mail and currency sorting devices, robotic ice bagging equipment, control panels, and pre-wired custom metal enclosures are all built and shipped globally from our 400,000 sq ft manufacturing facilities in the Dallas, TX area.

- Complex Document Sorting Equipment

- Control Panels

- Custom Brackets & Enclosures

- Robotics

- Custom Automation Equipment

- Tubular Frames

Infrastructure

AS9100:D, ISO9001:2015, ITAR Registered

- Work Zone Signage Trailers

- Transportation Signage

- Fleet Refueling Stations

- Ruggedized Shock Trays

- Power Conditioning Equipment

- Seismic Monitoring Equipment

- Floating Evaporative Systems

Aerospace & Defense

Regal has a stellar history of providing complex fabrication and assembly services to leading prime contractors and aircraft manufacturers for such items as aircraft interiors, seat shell sub-assemblies, ground support equipment, control panels, and electromechanical sub-assemblies. From small sheet metal and machined parts to complex custom enclosures and top-level product assemblies, Regal’s skilled craftsmen and vertically integrated in-house “one-stop shop” capabilities make us an attractive vendor to defense and aerospace customers desiring a supply chain consolidation solution. As an AS9100:D certified and ITAR registered company with strong financial backing and tremendous in-house engineering support and manufacturing capabilities, our lengthy experience in aerospace and defense production, DCAD buy-offs, first article inspection requirements, traceability, and comprehensive record keeping make us the ideal manufacturing partner.

- Aircraft Seating Components & Assemblies

- Aircraft Trays & Carts

- Ground Support Equipment

- Control Panels

- Missile Components

- Custom Cables and Harnesses

Communications

Regal Research is located in the heart of the famed “Telecommunications Corridor” near the Dallas, Texas area. For over 40 years, we have produced a wide variety of communications related parts and assemblies for leading OEMs. We offer product development support and combine our in-house electrical and mechanical assembly capabilities with our broad metal fabrication capabilities to provide a powerful contract manufacturing solution for customers developing and producing communications related products.

- B-to-B and B-to-C Kiosks

- 3D Teleconferencing Equipment

- Control Panels

- Card Cages

- Fan Trays

- Custom Enclosures

- Rackmount Assemblies & Wiring

Custom Data Center Solutions

- Server racks

- Modular data center structures

- Electrical enclosures and containment solutions