Capabilities

Regal Research is your one-stop-shop for world-class mechanical product fabrication services.

- Engineering Support

- Precision Sheet Metal Fabrication

- Precision Machining

- Mechanical Assembly

- Electrical Assembly

- Welding

- Wet & Powder Coat Painting

- Sub-Assembly Manufacturing

- Complete Product Manufacturing

- Packaging and Warehousing

- Equipment List

Engineering Support

Though Regal Research is primarily a ”build-to-print” fabricator, we pride ourselves in offering engineering support that makes us a true partner to our customers. Regal’s degreed mechanical and electrical engineers can assist in the conceptual phase of product development.

Though Regal Research is primarily a ”build-to-print” fabricator, we pride ourselves in offering engineering support that makes us a true partner to our customers. Regal’s degreed mechanical and electrical engineers can assist in the conceptual phase of product development.

- Design for Manufacturability

- Material Suggestions

- Creative Tooling Design

- Cost Reduction

- Quality Improvement

- Drawing Package Support

CAD Support

We use the industry’s best CAD Systems to support our customers’ needs, which allows us to accept our customers’ engineering data directly, without translation in most cases. We can create CNC programs directly from the engineering model files, reducing the risk of input errors, and shortening the manufacturing cycle. We also support electronic file exchange via our secure FTP site. For more information regarding FTP, contact Brian at 888-589-9925

CAD Systems supported include:

- Solidworks

- Pro-Engineer Wildfire

- Creo

- Autodesk’s Inventor Series

- UGS NX Series

Precision Sheet Metal Fabrication

Our high speed Trumpf CNC laser & punch presses feature auto-index of all tool locations and 24/7 lights out production with automated material handling systems. Additionally, our prototype cell emulates our production equipment, providing flexibility on quick turn pre-production and concept parts. We utilize two fully automatic Material Management Systems to allow us extended periods of unmanned, lights out manufacturing. Sheet metal fabrication and brake programming is handled using Trumpf’s Boost software, so we can program directly from our customers engineering data.

Our high speed Trumpf CNC laser & punch presses feature auto-index of all tool locations and 24/7 lights out production with automated material handling systems. Additionally, our prototype cell emulates our production equipment, providing flexibility on quick turn pre-production and concept parts. We utilize two fully automatic Material Management Systems to allow us extended periods of unmanned, lights out manufacturing. Sheet metal fabrication and brake programming is handled using Trumpf’s Boost software, so we can program directly from our customers engineering data.

Precision Sheet Metal Fabrication Highlights:

- Three High Wattage Trumpf Lasers

- Three Trumpf Punch/Laser Combo Machines

- One Trumpf 5000 Series Punch

- 60″ x 144″ Sheet Size Maximum

- Two Automated Material Management System

- Twelve CNC Press Brakes (Many are Fully Programmable Offline)

- Brake Capacity to 240 TONS

Precision Machining

We specialize in close-tolerance milling and turning of small to medium size parts in a number of different materials, including aluminum, steel and stainless steel as well as a variety of different alloys and plastics. Regal regularly holds tolerances of .0005 of an inch and offers pre-production prototype services through high-volume production runs. Many of our mills are equipped with automatic pallet changers and high-speed spindles. CNC Programming is done using CNC Software’s Mastercam, which allows us to program directly from our customers engineering data.

We specialize in close-tolerance milling and turning of small to medium size parts in a number of different materials, including aluminum, steel and stainless steel as well as a variety of different alloys and plastics. Regal regularly holds tolerances of .0005 of an inch and offers pre-production prototype services through high-volume production runs. Many of our mills are equipped with automatic pallet changers and high-speed spindles. CNC Programming is done using CNC Software’s Mastercam, which allows us to program directly from our customers engineering data.

Precision Machining Highlights:

- 5 Axis Capabilities

- 6 CNC Horizontal Milling Machines

- 13 CNC Vertical Milling Centers

- 8 CNC Turning Centers

- High Speed CNC Milling – 12,000 RPM

- 40″ X 25″ X 80″ CNC Milling Capacity

- Small Part CNC Turning to 6″ Diameter

- Many Conventional Mills & Lathes

- In-house Tool Grinding & Presetting

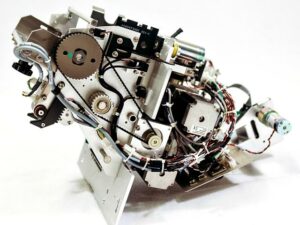

Mechanical Assembly

Regal Research’s expertise in complex

mechanical assembly is just one of many things that sets us apart in the contract manufacturing marketplace. This capability allows us to play an expanded role in providing true turnkey solutions to our customers. Our mechanical assembly department is equipped with the finest automated equipment available and is staffed by an expanding and highly experienced team.

mechanical assembly is just one of many things that sets us apart in the contract manufacturing marketplace. This capability allows us to play an expanded role in providing true turnkey solutions to our customers. Our mechanical assembly department is equipped with the finest automated equipment available and is staffed by an expanding and highly experienced team.

Mechanical Assembly Highlights:

- Haeger auto-insertion machines

- Auto-feed option attached for greatest efficiency, reliability

- Average employee experience on machines is over 6 years

- Solid rivets – to Military Standard specifications

- Milford tubular rivets

- Pop rivets

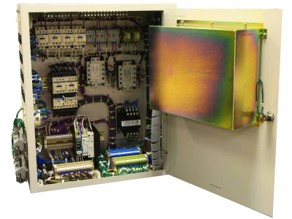

Electrical Assembly

Many of the complex mechanical assemblies that we produce require the additionof electrical and/or electronic components to achieve their full functionality. We maintain a fully-equipped electrical assembly and test department, staffed by the industry’s finest electrical assembly, test, and inspection personnel. Regal’s assembly staff is certified to leading industry standards, and is equipped with the tools, skills and experience to provide first-class assembly support to any program.

We fabricate sensitive defense electronics technology for Raytheon, Lockheed-Martin, Rockwell, and other top-tier technology firms, as well as leading medical, semiconductor equipment, and industrial companies worldwide.

Electrical Assembly Highlights:

- AS9100 & ISO9001 registered quality system

- J-Std. certified solder technicians

- Tools and equipment calibrated to NIST-reference standards

- ESD-protected area (electro-static discharge)

- Average experience of 30+ years

Welding Highlights:

Regal Research has two welding departments, which are instrumental in allowing us to offer the finest turnkey manufacturing services available. Providing automated robotic and manual welding services, we weld everything from light gauge aluminum and stainless steel, to precision machined components, to good old-fashioned ” pig iron” .

Regal Research has two welding departments, which are instrumental in allowing us to offer the finest turnkey manufacturing services available. Providing automated robotic and manual welding services, we weld everything from light gauge aluminum and stainless steel, to precision machined components, to good old-fashioned ” pig iron” .

An active participant in some of our most complex projects, our weld department benefits our customers through early involvement in the manufacturing cycle, helping to ensure optimum process flow and top-quality finished goods.

Certified Welding Highlights:

- Fully Automated Robotic Laser Fusion Welding

- Certified Welding Personnel

- MIG, TIG, ARC Welding

- Spot welding – including aluminum

- Miller Welding Equipment

- Acorn tables for rapid, precise fixturing

Wet & Powder Coat Painting

Nothing is more critical to the final appearance of your parts than the finishes applied. In an effort to control every phase of the manufacturing process to ensure the finest quality parts for our customers, Regal Research has a robust collection of finishing departments. Parts are prepared using automated, semi-automated, and manual debur processes, as well as Chem Film and other cleaning processes.

PAINT & FINISH DEPARTMENTS

Debur, Grind & Polish

Debur, Grind & Polish- Chem film & zinc phosphate plating

- Conveyorized powder paint

- Manual small to medium powder paint

- Large structure powder paint

- Multi-color silkscreen

Sub-Assembly Manufacturing

More the just a mechanical fab shop, Regal specializes in Sub-Assembly contract manufacturing giving our customers a plug and play solution for them to integrate into their proprietary final product level builds by combining our comprehensive in-house manufacturing capabilities. We can take a product from design through completion with little or no outsourcing of parts and services; a factor that gives Regal a distinct quality and delivery advantage over our competition.

More the just a mechanical fab shop, Regal specializes in Sub-Assembly contract manufacturing giving our customers a plug and play solution for them to integrate into their proprietary final product level builds by combining our comprehensive in-house manufacturing capabilities. We can take a product from design through completion with little or no outsourcing of parts and services; a factor that gives Regal a distinct quality and delivery advantage over our competition.

Product Examples Manufactured for Other Companies:

- Custom High-Powered Computing Enclosures

- Custom Medical Incubation Cabinets

- Complex Cash & Mail Sorting Sub-Assemblies

- Automated Ice Bagging Equipment

- 3D Teleconferencing Equipment

- Fleet Fueling Payment Stations

- Aircraft Ground Support Equipment

- Defense Mortar Tracking Units

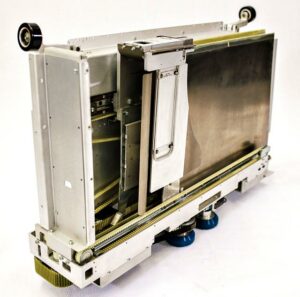

Product Level Manufacturing

Regal Research also provides the complete top level build of many products utilizing our vast in-house contract manufacturing services. The products we build are complex mechanical and electromechanical assemblies that require the integration of fabricated components with electronics, including backplanes and custom PCBAs. We have many years of experience integrating cables and wiring into multi-tiered fabricated assemblies for a wide variety of customers. Regal Research possesses the managerial and technical skills to support programs requiring the full spectrum of electromechanical expertise.

Mechanical and Electrical Assembly

Mechanical and Electrical Assembly- Testing to Customer Requirements

- “Ship to Stock” Inspection

- Custom Packaging to Customer Specifications

- Managed Inventory Programs

- Scheduled shipments

Packaging and Warehousing

Given today’s constant economic pressure to lower inventory levels without adversely affecting lead times, many of our customers have established a partnership with us to package, inventory, and ship their products on demand. Regal has over 50,000 sq ft of warehouse and packaging space as well as several acres of outdoor storage. We offer programs that are customized to meet each customer’s unique product fulfillment requirements, including customized labeling and freight pick-up management.

Fulfillment Services

Fulfillment Services

- Computerized inventory management

- Customized packaging design and manufacturing

- Warehousing at our Plano campus and offsite per customer requirements

- Shipping on demand

Equipment List

At Regal Research & Mfg., we have an impressive inventory of the most advanced, state of the art lasers and machinery in our industry. Click the button below to view a list of the various equipment that we use to ensure the highest possible quality and craftsmanship in each and every job.